Groz-Beckert Showcases Textile Innovation at ShanghaiTex 2025

From December 16 to 19, 2025, the global textile industry will gather at ShanghaiTex at the Shanghai New International Expo Center (SNIEC), where Groz-Beckert will present its latest highlights and innovations across its five product areas – Knitting, Weaving, Nonwovens, Sewing, and Spinning – at Hall N3, Booth A05.

Innovations Across Five Product Divisions

Knitting

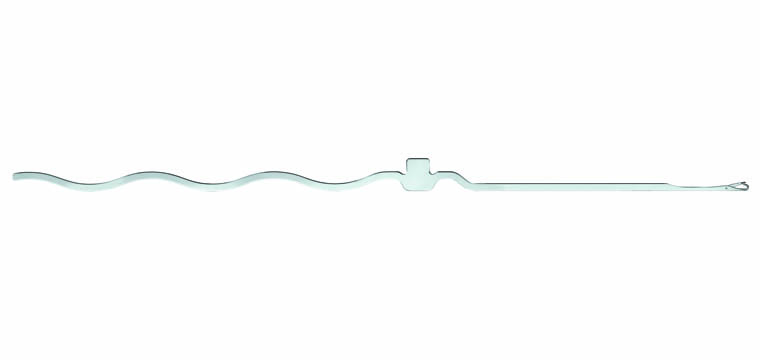

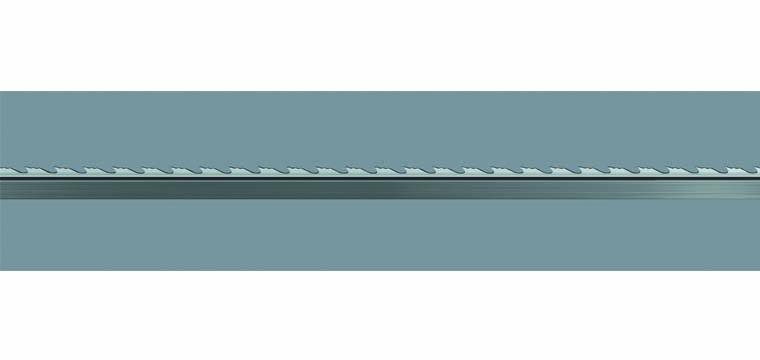

In the Circular Knitting segment, the spotlight will be on the LCmax™, the next generation of energy-saving needles. Featuring a pioneering wave-shaped shank geometry, LCmax™ ensures optimal energy efficiency, reduced friction, and ease of handling – delivering maximum performance with minimal energy consumption. Additionally, the cooperation with machine builder BORGFLY will be presented. Together, a new LCmax™ needle with an customized hook geometry has been developed. The first prototype of this specialized needle was delivered after just four weeks.

In collaboration with PAILUNG, Groz-Beckert introduces two new knitting systems:

a transfer needle and a compound needle.

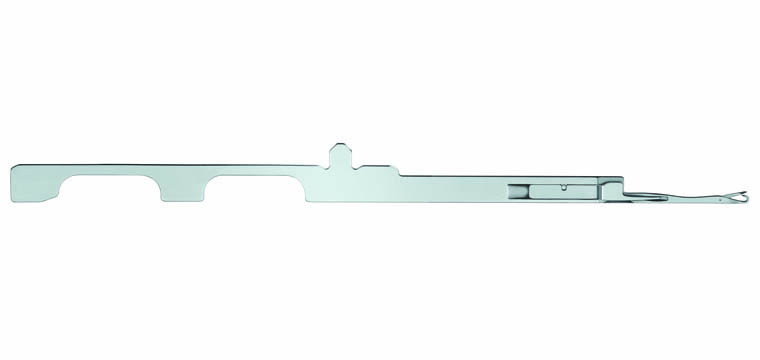

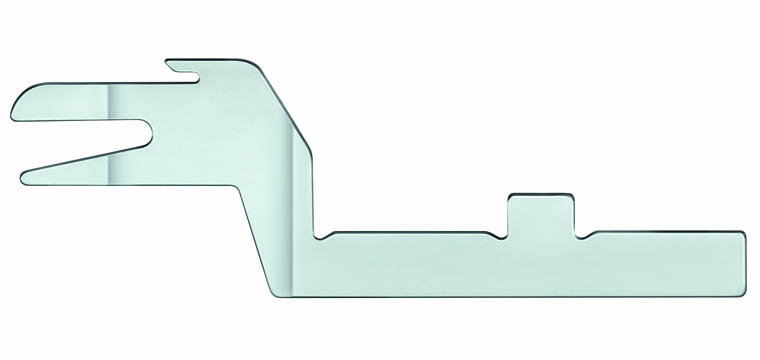

- The transfer needle Vo-Spec. 94.41-30 G 0010 sets a new industry benchmark with a needle thickness of just 0.30 mm and a 0.15 mm thin transfer clip, making it the finest of its kind. This precision enables exceptionally reliable loop transfer and opens new creative possibilities for ultra-fine fabrics.

- The new compound needle offers enhanced productivity, process reliability, and durability – even at high production speeds or when processing demanding yarns.

For applications using staple fiber yarns, the SAN™ SF staple fiber needle and SNK SF sinker combination reduces contamination and extends cleaning intervals, boosting overall efficiency.

In Flat Knitting, the cooperation with machine builder CIXING will be highlighted, where the durable VOSA-SPEC. 89.60-45 G02 needle has been developed.

In addition, two specialized needles take the stage:

- The SAN™ TT, designed for particularly tight loops, ideal for technical and medical textiles.

- The SAN™ FY, engineered for processing uneven effect yarns, ensuring flawless fabric appearance even with complex designs.

The Legwear Segment will showcase dur™ needles, known for their extreme durability and precision in fine hosiery production. Complementing these are new system parts, including toe closing components that guarantee uniform loop transfer and perfect fabric finish.

In Warp Knitting, Groz-Beckert presents its expanding module range and an innovative guide needle for Piezo-Jacquard machines, setting new standards in precision, stability, and efficiency for loop formation.

Weaving

Groz -Beckert’s Weaving division will demonstrate how precision and reliability in preparation and accessories can elevate fabric production quality and efficiency.

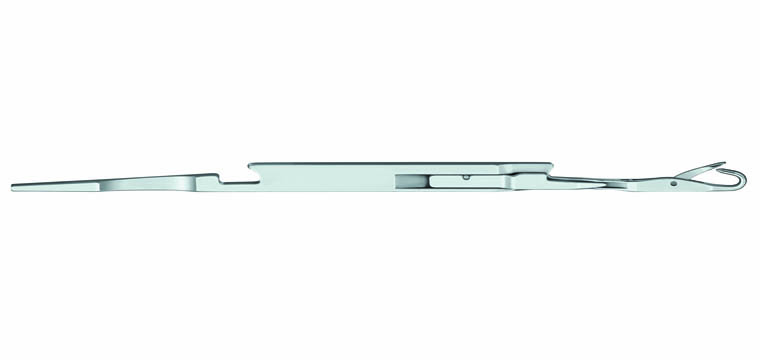

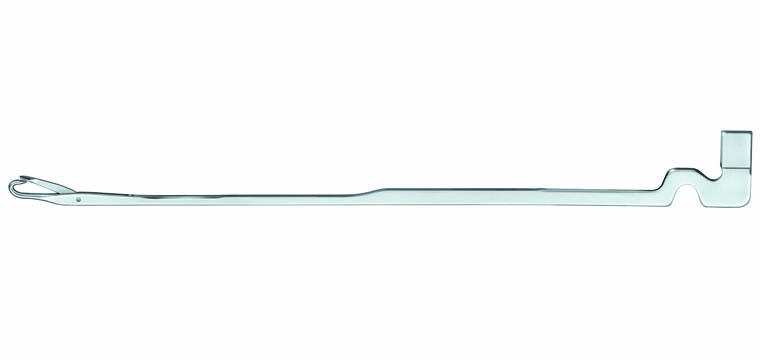

The portfolio includes heald frames, healds, warp stop motions, drop wires, and reeds, all compatible with major weaving machines and tailored to the diverse requirements of fashion, home, and technical textiles. Special focus will be on Groz-Beckert reeds, valued for their technical precision and versatility. Whether in high-speed production or complex technical fabric manufacturing, these reeds ensure perfect thread guidance and flawless results.

Nonwovens

In Nonwovens, Groz-Beckert showcases advanced solutions for both traditional needling and carding applications.

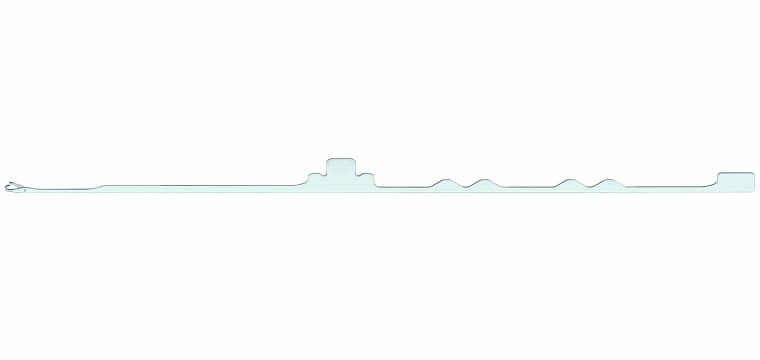

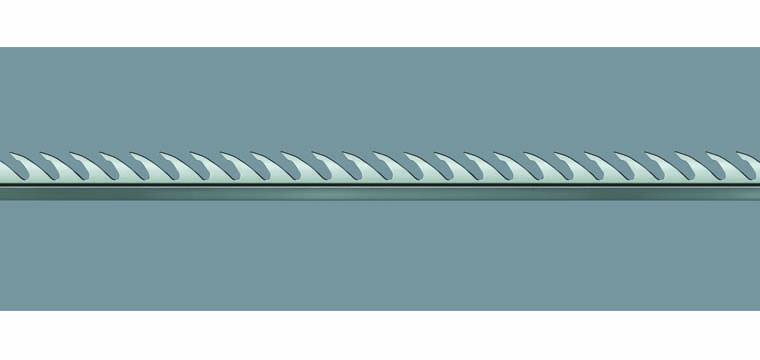

Focusing on the card clothing sector, the product area presents its innovations from the Groz Beckert InLine family: The SiroLock™ plus worker and doffer wires. Their special geometry enhances machine availability and ensures consistently high carding quality across nonwoven production processes.

Sewing

The Sewing division highlights their special application needles, tailored to meet the demands of advanced sewing applications:

- SAN™ 5.2 – for technical textiles such as airbags, offering greater stability and secure loop pick-up.

- SAN™ 6 – ideal for woven fabrics like denim, with enhanced durability through GEBEDUR™ coating.

- SAN™ 10 and SAN™ 10 XS – designed for fine knits and delicate materials requiring precise stitching.

- Litespeed™ – the latest innovation, developed for high-speed or dense material sewing where needle heat buildup is critical. Its geometry reduces friction and heat, ensuring smoother processes.

- MR needle – suitable for multidirectional sewing operations offering consistent performance across changing stitch directions.

- DBxK5 SAN™ 1 – designed for embroidery on hard and sturdy materials ensuring reliable performance and clean embroidery results.

Spinning

For the Spinning industry, Groz-Beckert introduces a maintenance-free cylinder wire designed for longer service life and reduced maintenance costs. Further innovations include enhanced revolving tops optimized for fine yarn processing and stationary flats featuring a robust new aluminium profile – ensuring precision, durability, and reliability in every stage of the spinning process.

Source: Groz-Beckert